Your Questions Answered: Infrastructure Monitoring through Ackcio & tailored:systems Technologies Webinar

Digital Monitoring Drives Productivity, Safety Gains on Infrastructure Projects

End-to-end digital solutions are transforming geotechnical monitoring of high-stakes infrastructure projects such as dams, bridges and tunnels, driving productivity gains by protecting assets and people and reducing costs and risks.

These automated, user-friendly systems can reduce monitoring costs by up to 70% while improving risk management with reliable, actionable real-time data, according to a webinar by Ackcio and tailored:systems. To watch the full session, click here. Read on for key questions that came out of the webinar.

1. How does digital monitoring affect productivity?

The infrastructure industry is a huge global business, worth approximately $13 trillion and employing some 180 million people around the world. And, yet, over the past 20 years, it has been a productivity laggard compared to other major international industries.

“We are spending billions of dollars in infrastructure projects, but we’re not really getting all the value out of that,” says Oscar Guevara, Chief Business Officer of tailored:systems, a digital monitoring systems integrator and technology partner based in Barcelona, Spain. Slow technology adoption, including for monitoring, and an over-reliance on legacy solutions is largely to blame. Digital solutions are key to driving efficiencies, cutting costs and increasing productivity.

2. How has infrastructure monitoring evolved?

Geotechnical monitoring has been around for almost 100 years, and its evolution has followed larger technology advancements. While early, manual systems required a worker to gather readings on-site, in the 1970s, automatic cabled dataloggers came onto the market. And then, in the ‘90s, wireless dataloggers removed the need for cables.

“The real revolution came ten years ago with IoT protocols,” says David Gomez, Chief Sales Officer with tailored:systems. Data collection via low-powered radio networks made automated monitoring affordable and reliable, and that technology continues to evolve. The latest development has been in cloud computing, while the future will see AI and machine learning further expanding monitoring.

3. Are there good use-cases for legacy systems?

While wireless technologies are increasingly popular, there are still a lot of manpower-based and cabled solutions on job sites around the world. In some cases, such as when low-frequency readings are needed, they are still the best option. But a cable-based solution takes a lot of time for planning and deployment, and maintenance is expensive. Plus, electromagnetic interference can create noise that hurts data reliability. It’s all about balancing tradeoffs in reading frequency with costs. In most cases, wireless technologies are most cost-effective.

4. Where is monitoring technology headed?

“We all understand wireless is the way forward,” says Mobashir Mohammad, Ackcio’s Co-Founder and Chief Technology Officer. While short-range communication technologies, such as WiFi, work well for home or office, they can’t handle the spread of most geotechnical applications. For coverage and scale, licensed technologies, such as 3, 4 and 5G, provide enormous bandwidth but consume a lot of energy, and many sites don’t have reliable cellular coverage. That’s where LPWAN technologies like WiSun and LoRa come in. Battery-powered, they can last for years and provide the coverage needed for monitoring infrastructure projects.

5. What are the different types of LPWAN networks?

Mobashir explained how LPWAN technology has two main types of networks. The simplest, a star topology, can have multiple devices that communicate directly with a central gateway receiver. Easy to implement, with very low power consumption, a star topology is not scalable, is vulnerable to obstructions or signal interference, and is restricted to a single point of range.

Compare that to a mesh technology, such as the Ackcio Beam, in which the nodes communicate with each other, overcoming the reliability and scalability issues of the star topology. Self-healing, secure and scalable, with an on-demand downlink for remote reading adjustments, a mesh system provides greater reliability, flexibility and range.

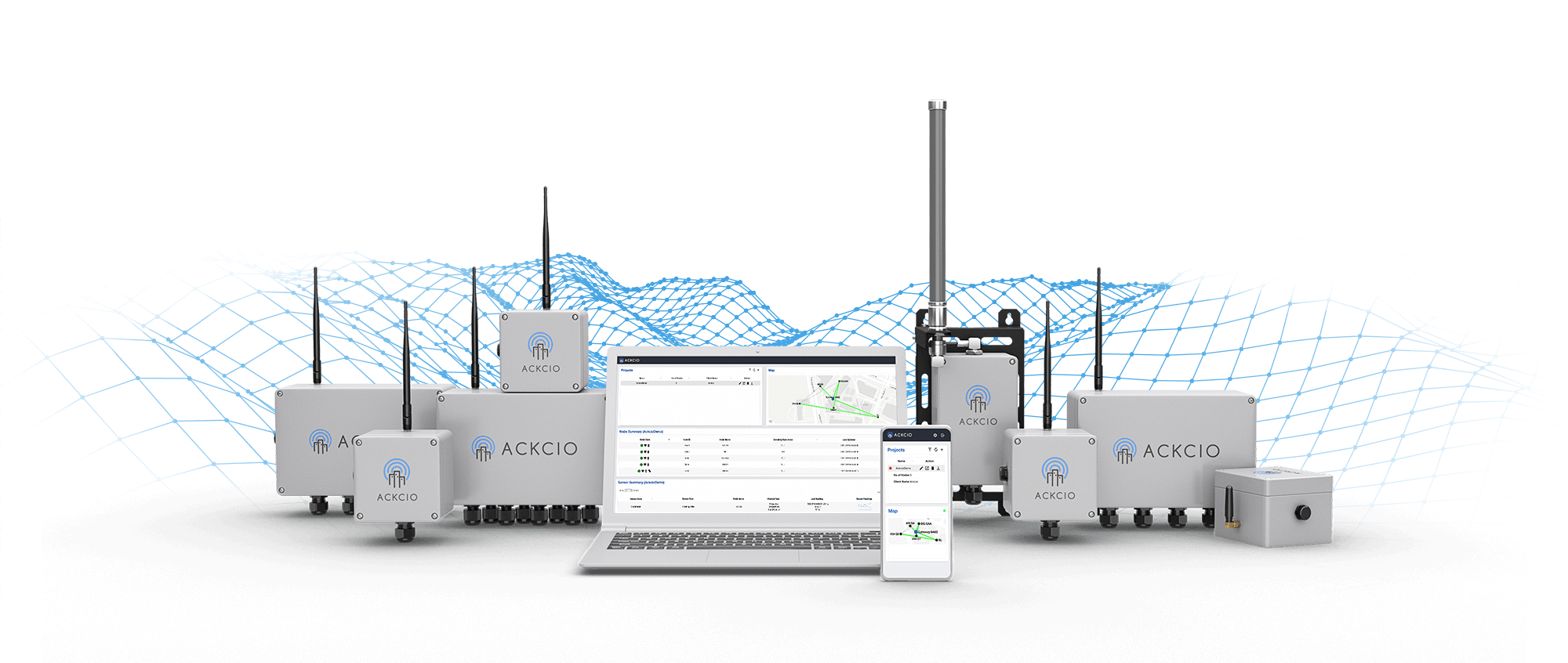

6. What are Ackcio’s main products?

Shaun Ahern, Ackcio’s Global Sales Director, explained how Ackio Beam, the company’s flagship product suite, works. It starts with a variety of nodes that integrate with all leading analogue, vibrating wire, and digital sensors, as well as wireless Tiltmeter nodes and Repeater Nodes to extend coverage. There’s also the Gateway, Ackcio’s central receiver, and proprietary software, including Snape, which runs on the gateway, and Nimbus, Ackcio’s Android mobile application for onsite deployment and configuration. The whole system is encrypted, and runs on the edge, with the Gateway pushing data to the client’s server or visualization software of choice.

“It is totally private to the users,” Shaun said. “We do not store any of your information.”

7. Does Ackcio integrate with other monitoring hardware and software?

Ackcio takes an agnostic approach, integrating with an ever-increasing range of sensors at one end, and with data visualization and analysis software, including IoTailor, tailored:systems proprietary cloud platform, at the other.

IoTailor offers users a lot of flexibility, which is important because infrastructure monitoring projects vary greatly. Clients can change widgets, maps and themes, set thresholds and alarms, and see project data and data about the monitoring system’s health on its intuitive interface.

8. What should I look for in a digital monitoring implementation partner?

Oscar explains that along with technical knowledge, the ideal partner also understands the infrastructure industry and how infrastructure projects work. He also recommends finding a flexible solution that’s adaptable to all use cases. And finally, it should be scalable to grow with the project.

9. Do Ackcio Nodes work in manholes and utility holes? How do the Repeater Nodes work?

Utility hole projects are very challenging, but a mesh solution, such as Ackcio Beam, can overcome a star system’s range limitations in an underground environment. David shared a use case from an underground Metro station in Madrid to monitor the stability of a rail track and walls with Ofiteco, a leading instrumentation and monitoring company in Spain. Ackcio Tiltmeter Nodes (BEAM-TM) were installed on the rail platform to monitor longitudinal and perpendicular twists, and more were deployed on the sidewalls of the station. An Ackcio Gateway (BEAM-GW) was installed in a room on the platform 150-200 metres away but without a direct line of sight to the Nodes. The system is reliably transmitting real-time tilt readings to the Ofiteco monitoring software for site personnel to analyze.

10. How does the network cope when the Gateway loses power?

Ackcio has multiple layers of redundancy to ensure a power outage does not cause data loss, which could result in a stop-work order.

Ackcio’s Gateway has a backup power source and onboard memory so it can operate in a unique low-power mode when the power supply is disrupted. This allows the network to remain live, on-site, and continue receiving the sensor data. Once the power is restored, the Gateway will automatically sync and send the stored sensor data to the client’s server or chosen software.

The Nodes also have onboard memory and a background sync feature which ensures data reliability in case of network downtime. The Nodes will continue to take sensor readings and automatically retransmit these readings when the network is re-established.

11. How many hops can Ackcio Beam make?

Ackcio can achieve up to 12 hops, allowing for a greater aggregate range than star topology systems, which are limited to a single hop. This is especially useful in challenging underground environments. To learn more about how Ackcio is able to go deeper and further, click here.