Challenge

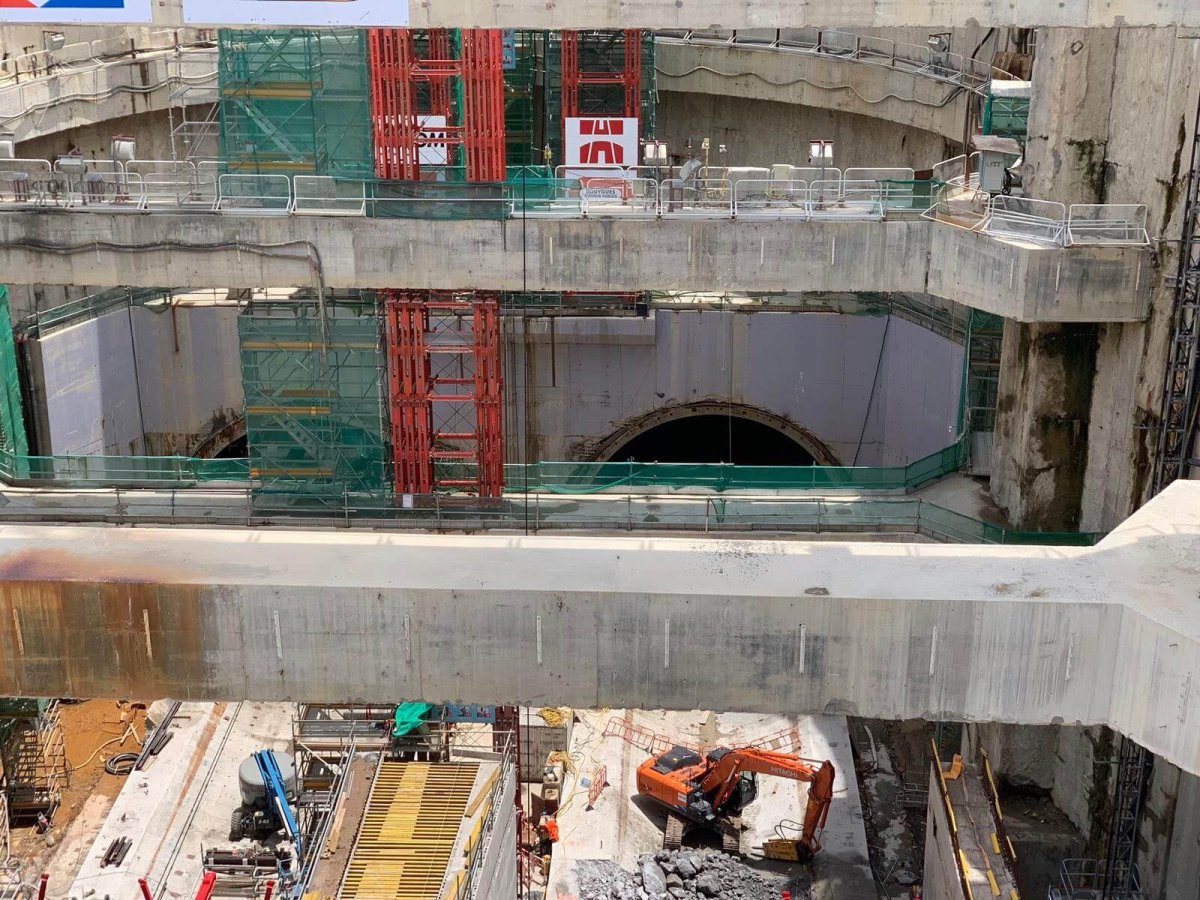

Tunnel boring to extend the last section of Singapore’s Mass Rapid Transit (MRT) Thomson Line through the central Marina Bay neighbourhood presented potential risks to nearby infrastructure, including an underground common services tunnel (CST) containing water and gas pipes and electrical and utility cables. The CST had to be monitored during construction to ensure that the nearby jacking and digging work did not compromise its stability and safety.

Soil Investigation, a Singapore geotechnical investigation firm, had the monitoring contract for the project, which used manual data collection.

This method had some serious drawbacks. Access to the tunnel was limited and tightly controlled. They had to apply monthly for a permit from the Public Utilities Board (PUB). There were limits on the number of workers who could go down into the CST and constraints on the timing and the duration of access.

“That is the problem,” says Shang Zhi Yang, an instrumentation engineer at Soil Investigation. “This is a tunnel monitoring project, and no worker is able to easily access the tunnel for readings.”

Not simply an administrative headache, this approach was also expensive. The permit fee per hour was approximately USD$110, and there was also labour cost. In total, Zhi Yang estimates manual data collection over the project’s two years cost USD$33,000.

And the manual readings only provided a moment-in-time snapshot of tunnel movement. With ongoing construction and tunnelling work, a real-time data stream would provide far greater insights to manage risk.

After manual monitoring for two years, Soil Investigation was looking to test an automated, real-time alternative to this labour-intensive, costly and outdated approach.

But at nearly 50 metres and four stories underground, there was no internet access via cellular, LAN or Wifi available inside the tunnel. Soil Investigation needed a system that could overcome these challenges.

Solution

Soil Investigation chose the Ackcio Beam wireless data acquisition solution, as its unique mesh system allows for far deeper and longer data transmission, even in challenging underground conditions, where other wireless solutions based on LoRa or 2.4GHz mesh networks have reliability issues.

Soil Investigation launched a four-month internal trial to test the viability and reliability of Ackcio’s real-time system while still collecting manual data. Its deployment comprised four Ackcio Beam Analogue 1-sensor Nodes (BEAM-AN-S1) monitoring four bi-axial tiltmeters. These sensors were located four stories underground, approximately 300-400 metres from the Ackcio Gateway (BEAM-GW) at the surface.

“The distance was too long,” Zhi Yang says for the signal to transmit from the Nodes to Gateway. An Ackcio Repeater Node (BEAM-RN) two stories underground acted as a mid-way signal relay to get the data to the Gateway two stories up at the surface.

During the trial, the Ackcio Beam solution reliably sent real-time data to the Repeater Node and then to the Gateway, which was connected to power from the service tunnel. The Gateway streamed data via FTP to Soil Investigation’s server, eliminating the need for workers to go underground for manual readings.

Ackcio and Soil Investigation are based in Singapore, so Ackcio was able to provide in-person training on how to install its devices, collect data, and troubleshoot. Ackcio team members even visited the tunnel site to evaluate where to place the Nodes.

“We worked very closely with the Ackcio team, they were very hands-on,” Zhi Yang says. “It was a very positive experience.”

Benefits

- Reliable communication in an underground environment

- Eliminates the need for manual data collection

- Ultra-low power consumption

- Remotely adjust reading frequency

- Easy to scale

Results

- Remote, real-time data access

- Decreased workforce costs

- Increased worker safety

- Improved risk management

- Real-time risk analysis

At the end of the trial, Soil Investigation was pleased with the results. The readings were steady and stable, proof that Ackcio can reliably send data even from four stories underground.

After this successful pilot project, Soil Investigation has since deployed Ackcio in a number of other projects.

“This was a pilot project to prove the Ackcio solution with results that surpassed our expectations,” says Zhi Yang.

Testimonial

We were very impressed with not only the range but even more so the reliability in such difficult conditions.

– Shang Zhi Yang, Instrumentation Engineer from Soil Investigation

Application

Infrastructure tunnel monitoring

Location

Singapore

Products Used

Monitored Sensors

Bi-axial tiltmeters

Measured Parameters

Tilt