Challenge

The North Baltic canal expansion project, which will widen and deepen the vital and increasingly popular man-made shipping channel connecting the North and Baltic Seas, involves dredging an enormous amount of soil – approximately 2.7 million m³ – that must be relocated.

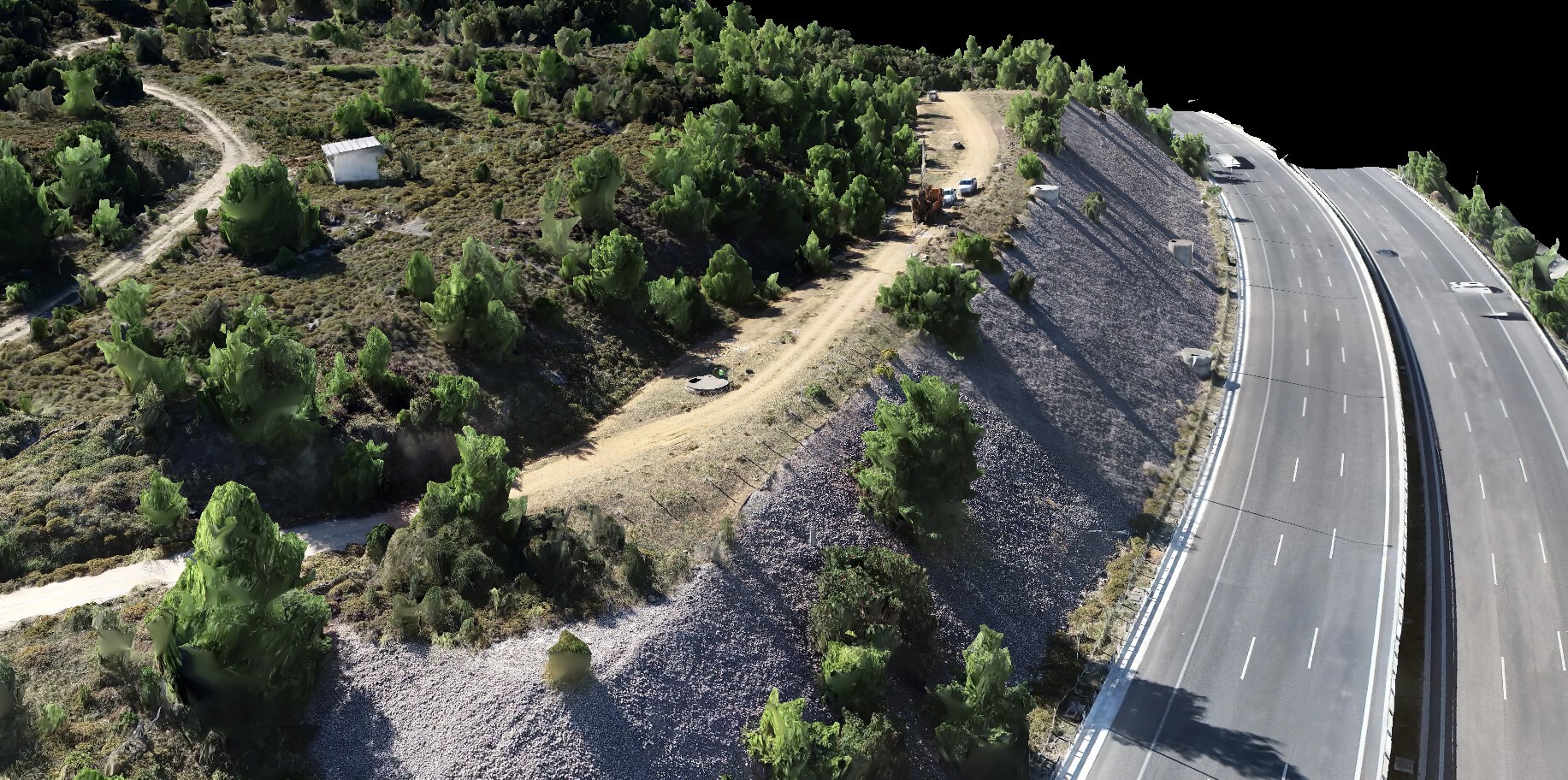

One of the project’s soil storage sites is in Flemhude, a small town in northern Germany, where a large, rectangular embankment approximately 500 metres long, 65 metres wide and up to 15 metres high is being built from about 130,000 m³ of dredged material.

Located between a lake just to its north and the A210 highway immediately to its south, the earthworks must be monitored on an ongoing basis to ensure it does not affect the stability of the busy route.

“When you bring that much soil here with that much mass, you have the risk that it can cause a base failure to the road and the lake,” says Benedikt Bruns, Managing Director of GEO-Inspector, a geotechnical firm based in Braunschweig, Germany. The company creates monitoring concepts, selects and installs sensors, and offers analysis, visualisation and interpretation of measurement results. “If this mass caused deformations, the highway could also be deformed and lifted. The cross slope of the roadway will be reduced, which will end up in unsafe driving conditions during rain events.”

Excess water could make driving conditions dangerous and require that a speed limit be imposed on the highway, which does not have one in normal conditions.

Solution

GEO-Inspector was hired to install the monitoring equipment, collect daily readings, and present the data to the client on its custom visualisation platform.

The original tender for the project stipulated the sensors that would be used: eight Measurand ShapeArrays and six Sisgeo digital H-level meters. The tender also called for different logger brands on the two different types of sensors.

“We were looking for a better solution,” Benedikt says. GEO-Inspector wanted to find a single data acquisition solution that would pair with both types of sensors to manage the monitoring project. “And that’s how we came to Ackcio, to bring these different sensors to one system.”

Ackcio is engineered to be sensor-agnostic, integrating with the Measurand ShapeArray and all other leading sensor brands as well as all of the most common monitoring data-presentation software, providing a truly end-to-end solution.

GEO-Inspector completed the installation in April 2021. Along with the sensors, which are installed in concrete shafts with approximately 20 cm-thick casings, they installed nine Ackcio Digital Nodes (BEAM-DG), located between 5 and 125 metres apart. The battery-powered nodes transmit readings to one solar-powered Ackcio Gateway (BEAM-GW), installed near the embankment. The Gateway then sends the data to the monitoring software for the team to analyse.

Since the installation, the system has reliably been sending daily readings from the field. Monitoring on the embankment is planned for six years, as soil settlement could continue to pose a risk to the highway.

This is the first time Benedikt and the GEO-Inspector team have partnered with Ackcio, and they’ve been pleased with the intuitiveness of its monitoring solution and the responsiveness of its customer success and engineering teams. They also appreciate the cost savings of approximately 40% compared to other solutions on the market.

“What I have found is that the system is very, very easy to use; it’s kind of self-explanatory,” Benedikt says. “And it’s a very stable system that is providing good quality results. We will definitely use Ackcio in future projects.”

Benefits

- Easy to install and use

- Reliable communication

- Eliminates the need for manual data collection

- Ultra-low power consumption

- No external power supply needed

Results

- Remote data access

- Reliable, real-time readings

- 40% cost savings

- Complete understanding of soil movement

Testimonial

We were looking for a better solution. And that’s how we came to Ackcio, to bring these different sensors to one system.

– Benedikt Bruns of GEO-Inspector shares his view on how Ackcio offers a single solution for various sensors in a single project.